6 Polymer-Based Additive Manufacturing: Fundamentals and Emerging Applications

Hussain Kawsar Chowdhury

Learning Objectives

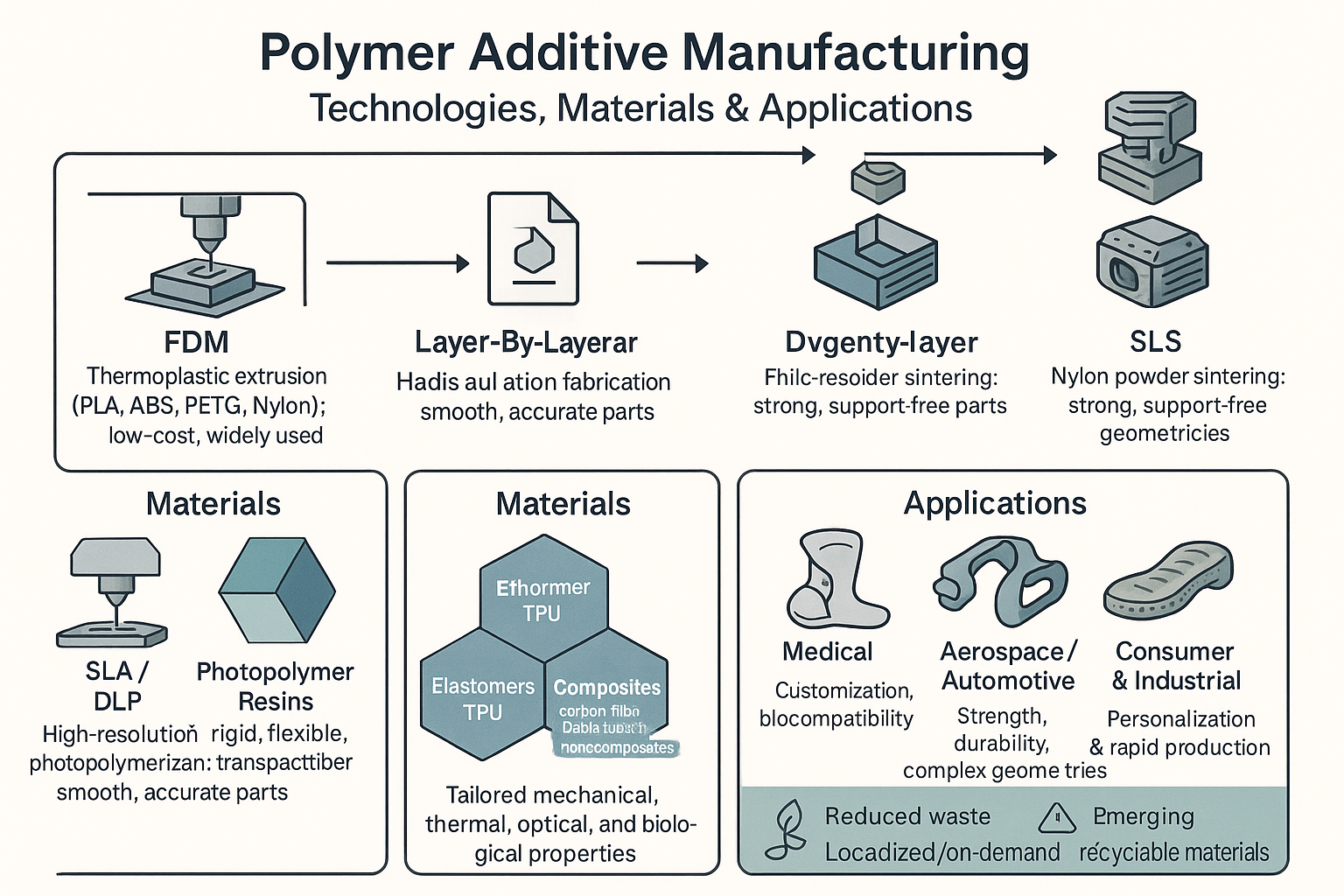

- The principles of major polymer AM technologies, specifically FDM, SLA/DLP, and SLS, will be described, including Fused Deposition Modeling (FDM), which uses a melted solid polymer filament, Vat Photopolymerization (SLA and DLP), which uses light to solidify liquid resin, and Selective Laser Sintering (SLS), which uses a laser to fuse polymer powders.

- The main categories of polymers used in AM (thermoplastics, resins, elastomers, and composites) will be categorized, specifying thermoplastics (like PLA, ABS, and Nylon), photopolymer resins (which can be formulated for biocompatibility or high rigidity), elastomers (for flexibility and shock absorption), and composite materials that incorporate additives like carbon fiber

- Key applications of polymer AM in fields like medical, aerospace, and industrial tooling will be identified, including its role in medical and healthcare for creating custom prosthetics and surgical planning models, in aerospace and automotive for producing lightweight components and rapid tooling, and in consumer products through personalization.

Introduction

Additive manufacturing (AM), commonly known as 3D printing, is a method that creates objects layer by layer directly from a digital file. Unlike traditional subtractive manufacturing, which removes material, AM adds only what is needed—making it both efficient and capable of producing highly complex shapes. Polymers are the most widely used materials in AM because they are cost-effective, easy to shape, chemically versatile, and suitable for both everyday and high-performance applications.

Polymer AM has moved far beyond simple prototypes. It is now used to produce functional parts, customized medical devices, lightweight aerospace components, and consumer products made specifically for individual users. The following sections describe the major polymer AM technologies, the materials they use, and the applications they enable, with a focus on clarity and real-world relevance.

Polymer Additive Manufacturing Technologies

Fused Deposition Modeling (FDM)

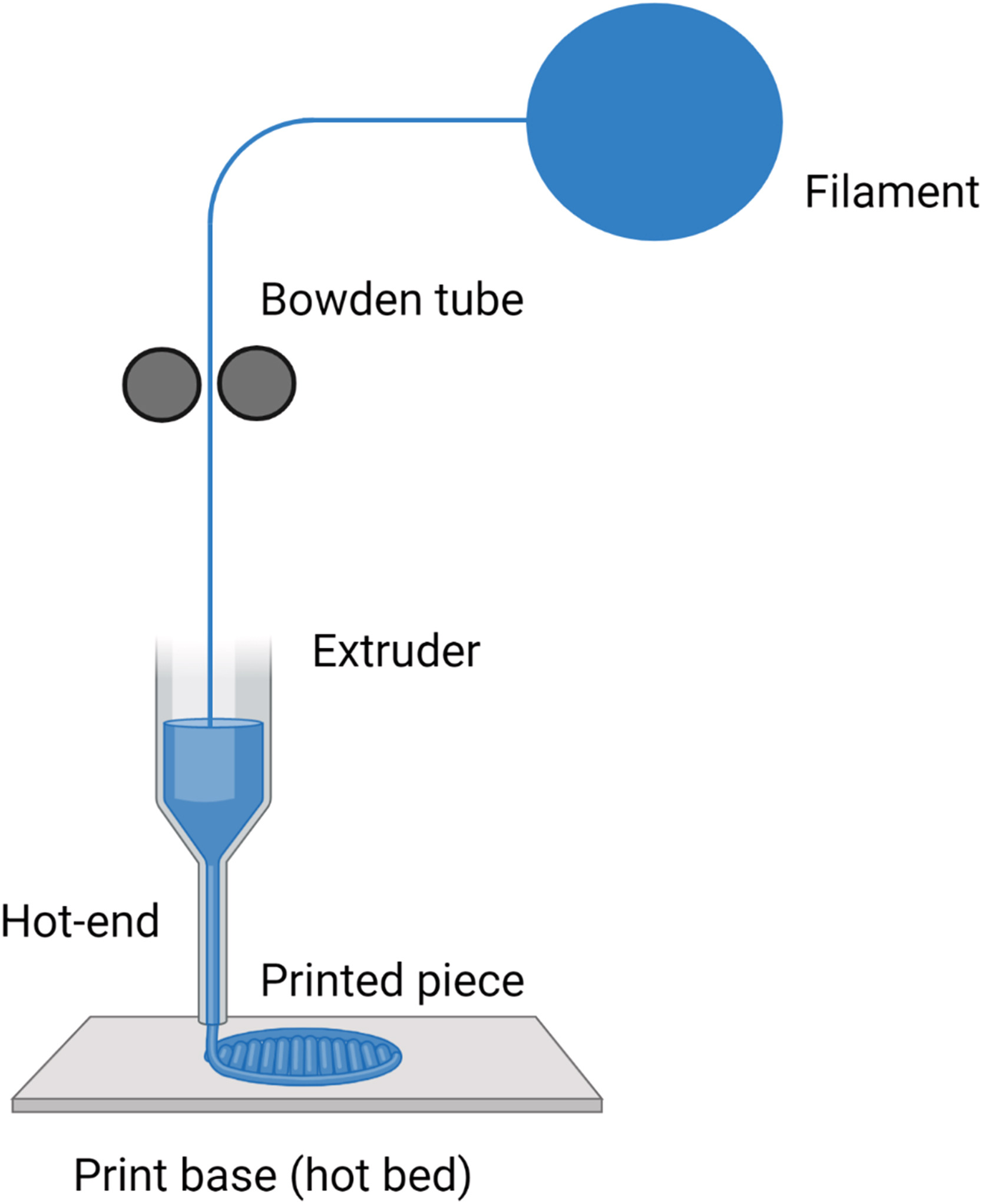

FDM is the most familiar and widely available polymer AM technology. In this method, a solid polymer filament—such as PLA, ABS, PETG, or nylon—is fed into a heated nozzle, melted, and precisely deposited in thin lines. As each new layer cools, it bonds to the previous one, slowly forming a three-dimensional object.

This process is popular because it is simple, affordable, and compatible with many thermoplastics. However, the printed parts often show visible layer lines and may be weaker in the vertical direction due to imperfect bonding between layers. Even so, FDM remains an essential tool for rapid prototyping, hobbyist printing, engineering design, and low-volume production.

Vat Photopolymerization (SLA and DLP)

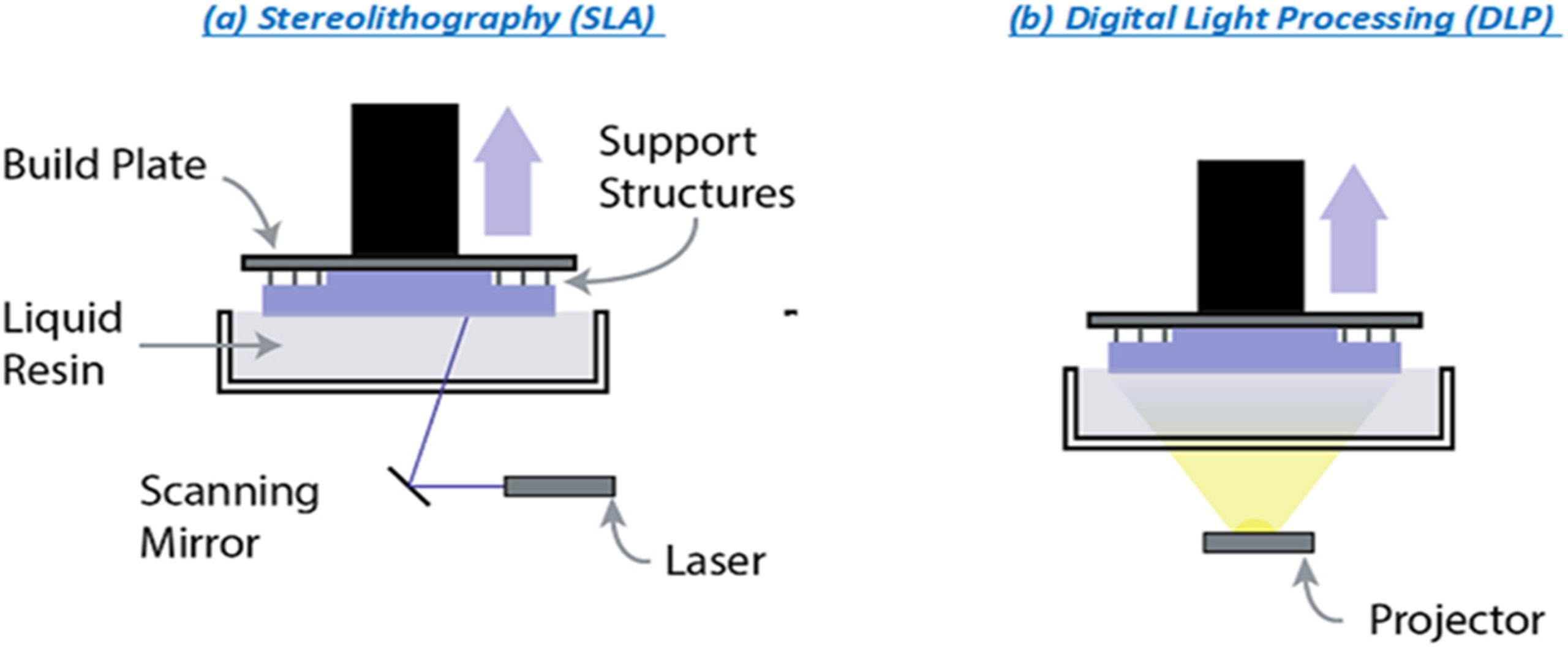

Vat photopolymerization processes, including Stereolithography (SLA) and Digital Light Processing (DLP), use light to solidify liquid resin. In SLA, a laser draws each layer onto the surface of the resin tank. In DLP, an entire layer is projected at once using a digital light pattern.

These technologies produce highly detailed, smooth, and accurate parts, making them excellent for dental models, jewelry, microfluidic devices, and small mechanical components. Resins can be tailored for stiffness, flexibility, transparency, or biocompatibility. However, printed parts usually require additional curing to reach full strength and may be more brittle than thermoplastic prints.

Selective Laser Sintering (SLS)

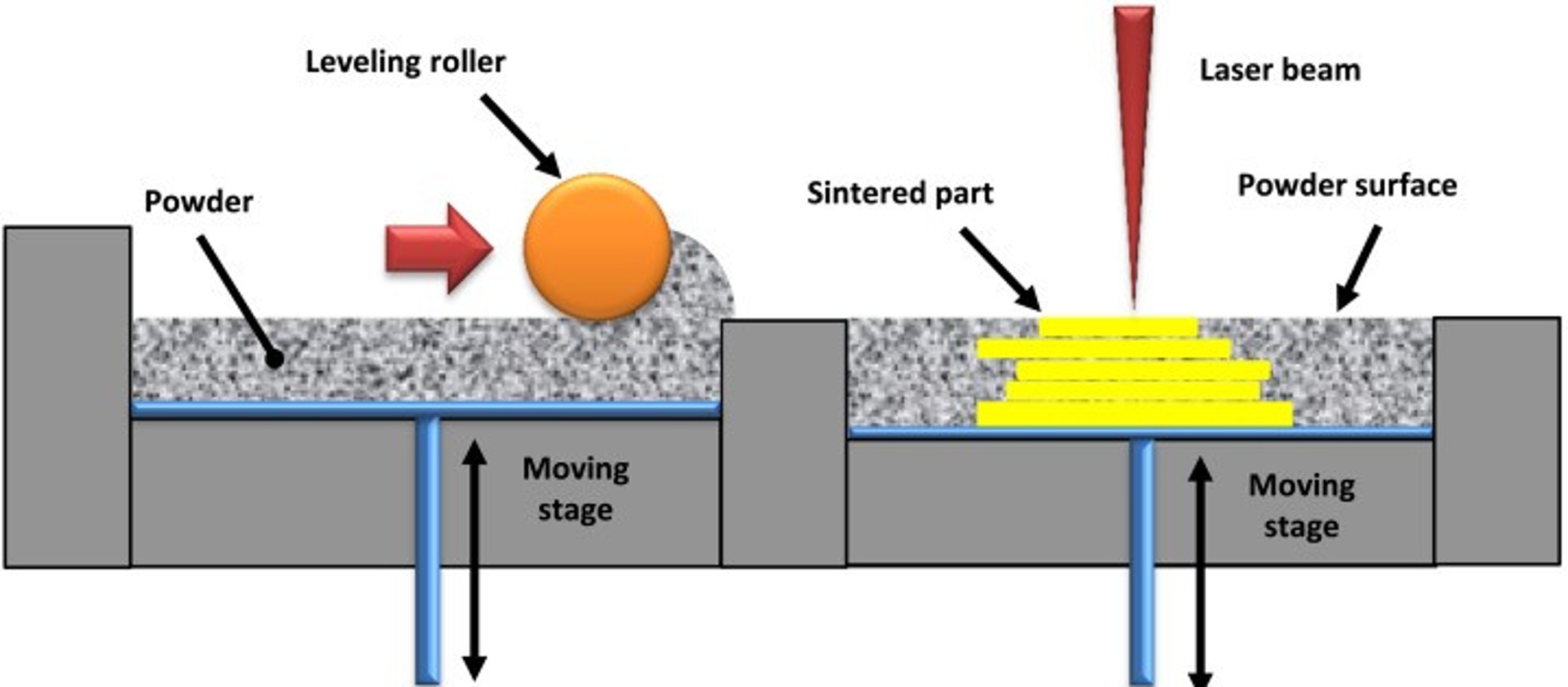

SLS is a powder-based technique where a laser selectively fuses polymer powders—most commonly nylon (PA11 or PA12)—into solid layers. Because unused powder supports the part during printing, complex geometries can be produced without the need for support structures.

SLS parts are known for their strength, durability, and excellent mechanical performance, making the process ideal for aerospace ducts, automotive housings, and industrial tools. The main drawbacks are the cost of equipment, the need to handle powder safely, and the possibility of porosity if the sintering energy is not properly controlled.

Other AM Technologies for Polymers

- Material Jetting: Deposits tiny droplets of resin and cures them instantly, enabling smooth, multi-material, and full-color prints.

- Binder Jetting: Uses a liquid binder to join polymer powder particles; final parts often require infiltration.

- Direct Ink Writing (DIW): Extrudes pastes or gels, including silicones and biomaterials, making it useful for soft robotics and tissue scaffolds.

Materials for Polymer Additive Manufacturing

Thermoplastics

Thermoplastics are the most common AM polymers because they can melt and re-solidify repeatedly. They exhibit a broad range of mechanical and thermal properties.

- Polylactic Acid (PLA): Easy to print and biodegradable; useful for prototypes and consumer items.

- Acrylonitrile Butadiene Styrene (ABS): Tough and impact-resistant; widely used for functional components.

- Nylon (PA12/PA11): Strong, flexible, and wear-resistant; excellent for SLS printing.

- PEEK and PEKK: High-performance polymers used in demanding aerospace and medical environments.

These materials vary widely in flexibility, heat resistance, and chemical stability, giving engineers many options for different applications.

Photopolymer Resins

Resins used in SLA/DLP printing cure under UV light and can be formulated for:

- High rigidity

- Flexibility or rubber-like behavior

- Transparency

- Biocompatibility (for dental and medical use)

- High-temperature resistance

Although resin prints offer exceptional resolution, many photopolymers remain brittle and have limited recyclability.

Elastomers

Elastomeric materials such as TPU provide flexibility and shock absorption. They are used to produce phone cases, robotics components, shoe midsoles, protective wear, and biomedical devices requiring softness or elasticity.

Composite Materials

Composite polymers incorporate additives to improve performance:

- Carbon fiber composites: Improved strength-to-weight ratio

- Glass fiber composites: Higher stiffness

- Nanocomposites: Electrical conductivity, thermal stability, or enhanced toughness

These materials allow AM to replace metals in more demanding environments.

Applications of Polymer Additive Manufacturing

Medical and Healthcare Applications

Polymer AM is widely used in healthcare because it enables customization, which is crucial for patient-specific devices.

Key applications include:

- Custom prosthetics and orthotics: Lightweight devices tailored to each patient’s anatomy.

- Dental devices: Aligners, crowns, and surgical guides produced quickly and accurately.

- Surgical planning models: Realistic anatomical models help surgeons prepare for complex procedures.

- Tissue engineering scaffolds: Porous structures support cell growth and regeneration.

Aerospace and Automotive Applications

The aerospace and automotive industries use polymer AM to reduce weight, simplify assembly, and shorten design cycles.

Common examples:

- Lightweight brackets and ducts printed from SLS nylon

- Rapid tooling and jigs to support manufacturing

- Functional prototypes for aerodynamic or ergonomic testing

- Cabin components made from flame-retardant polymers

These benefits translate into faster development and improved fuel efficiency.

Consumer Products and Personalization

AM enables the creation of custom eyewear frames, athletic shoe midsoles, sports equipment, and artistic pieces. Companies increasingly use AM to deliver personalized products that fit individual preferences or body measurements.

Industrial Tooling

Polymer AM is also used to produce molds, fixtures, and tools with features such as conformal cooling channels—improving the performance of traditional manufacturing lines.

Art, Design, and Architecture

Creative fields use AM to explore new geometric forms and produce large-scale structures. Architects employ robotic extrusion systems to fabricate walls, furniture, and decorative elements.

Sustainability in Polymer AM

AM contributes to sustainability by reducing waste, enabling local production, and supporting repairability through digital design. However, challenges remain:

- Many resins are difficult to recycle

- SLS powders degrade after repeated use

- FDM printers may release VOCs and ultrafine particles

Ongoing research focuses on biodegradable filaments, recyclable thermoplastics, and cleaner processing.

Discussion of a Peer-reviewed Journal

Polymer Nanocomposite Sensors with Improved Piezoelectric Properties through Additive Manufacturing

.

The selected peer-reviewed article investigates the development of a polymer-based nanocomposite resin designed specifically for vat photopolymerization additive manufacturing, with an emphasis on improving piezoelectric sensor performance. The authors focus on polyvinylidene fluoride (PVDF), a well-known piezoelectric polymer, and enhance its functionality by incorporating boron nitride nanotubes (BNNTs) as nanoscale fillers. The work addresses a critical limitation in polymer additive manufacturing: the lack of UV-curable resins that are both printable and functionally active, particularly for sensing applications.

Using an LCD-based SLA/DLP-style printer, the authors successfully demonstrate micro-scale printing of both neat PVDF-based resin and PVDF/BNNT nanocomposite resin. The study systematically evaluates structural phase composition, thermal behavior, rheology, mechanical properties, and piezoelectric performance. One of the most significant findings is that adding only 2 wt % BNNTs increases the piezoelectric voltage output of the printed sensors by up to 50%, while maintaining acceptable printability and mechanical integrity.

This chapter introduces the major polymer AM technologies (FDM, SLA/DLP, and SLS), the classes of polymers used in AM, and their applications across medical, aerospace, and industrial fields. The selected paper directly supports and expands on these concepts, particularly in relation to vat photopolymerization and advanced polymer materials. The authors formulated a series of PVDF-based resins by blending PVDF powder with UV-curable monomers, photoinitiators, and solvents, systematically varying the PVDF content from 20 to 40 wt %. To further enhance functional performance, 2 wt % BNNTs were introduced to create a nanocomposite resin. The resulting materials were evaluated comprehensively in terms of structural phase composition, thermal behavior, rheology, mechanical properties, printability, and piezoelectric response. An LCD-based 3D printer was selected due to its ability to cure entire layers simultaneously, enabling high-resolution printing at the micro-scale.

The paper provides a real-world case study of vat photopolymerization (SLA/DLP) in action, and demonstrates how these technologies are not limited to aesthetic or prototype parts. Instead, they can be used to fabricate functional, micro-scale sensors with tailored electrical properties. The incorporation of BNNTs into a PVDF matrix exemplifies how composite materials extend the capabilities of polymer AM, enabling properties such as enhanced piezoelectric response that are not achievable with neat polymers alone. The application focus of the article covers the medical, aerospace, and industrial sensing applications. The flexible, lightweight, and conformal nature of the printed PVDF/BNNT sensors makes them relevant for wearable sensors, structural health monitoring, and energy harvesting—applications that rely heavily on polymer AM’s ability to produce customized, lightweight components4.

References

(1) Cano-Vicent, A.; Tambuwala, M. M.; Hassan, Sk. S.; Barh, D.; Aljabali, A. A. A.; Birkett, M.; Arjunan, A.; Serrano-Aroca, Á. Fused Deposition Modelling: Current Status, Methodology, Applications and Future Prospects. Additive Manufacturing 2021, 47, 102378. https://doi.org/10.1016/j.addma.2021.102378.

(2) Al Rashid, A.; Ahmed, W.; Khalid, M. Y.; Koç, M. Vat Photopolymerization of Polymers and Polymer Composites: Processes and Applications. Additive Manufacturing 2021, 47, 102279. https://doi.org/10.1016/j.addma.2021.102279.

(3) 6.13 Additive Manufacturing of Multifunctional Nanocomposites and Composites. 2018, 380–407. https://doi.org/10.1016/B978-0-12-803581-8.10019-0.

(4) Govindarajan, R. S.; Ren, Z.; Melendez, I.; Boetcher, S. K. S.; Madiyar, F.; Kim, D.; Govindarajan, R. S.; Ren, Z.; Melendez, I.; Boetcher, S. K. S.; Madiyar, F.; Kim, D. Polymer Nanocomposite Sensors with Improved Piezoelectric Properties through Additive Manufacturing. Sensors 2024, 24 (9). https://doi.org/10.3390/s24092694.