Part 4: Common Processes for Polymer Material Fabrication

Introduction

Learning Objectives

- Explain the fundamental principles of common polymer fabrication processes, including extrusion, injection molding, compression molding, blow molding, and fiber spinning.

- Identify how each process influences the resulting polymer microstructure and properties.

- Correlate key processing parameters (such as temperature, shear rate, pressure, and cooling rate) with changes in molecular orientation, crystallinity, and morphology that determine mechanical, thermal, and optical behaviors of polymers.

- Analyze how different processing histories lead to variations in properties such as stiffness, toughness, clarity, and dimensional stability.

- Compare the structure–property outcomes among thermoplastic and thermosetting polymers fabricated by various methods, highlighting the role of crosslinking and flow behavior during processing.

- Evaluate common defects and residual stresses arising from improper processing conditions and explain how they affect product performance and reliability.

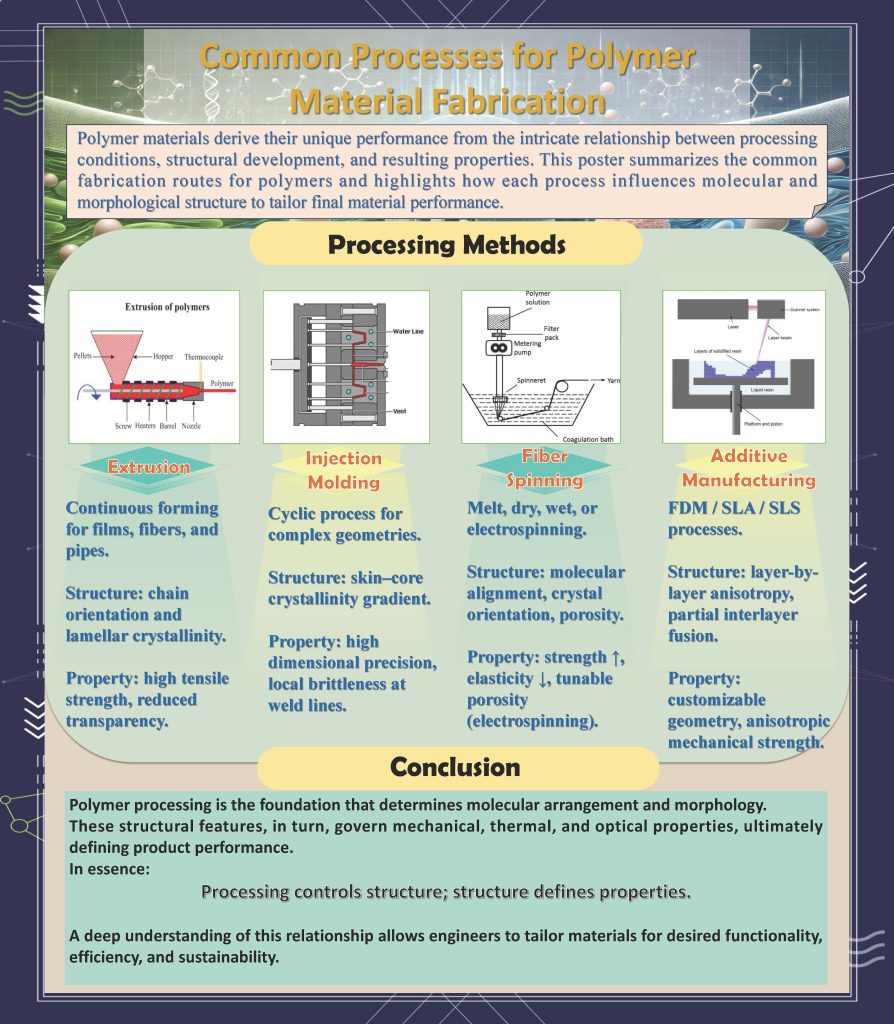

Why do two products made from the same polymer, with identical chemical structures and molecular weights, exhibit vastly different properties? One may be rigid and hard, while the other is soft and elastic; one could be transparent and tough, while the other is opaque and brittle. The difference lies not in their chemical properties but in their processing methods. During manufacturing, subtle variations in heating, cooling, shearing, or pressure can significantly rearrange polymer chains, alter crystallinity, control molecular orientation, and ultimately modify the material’s performance. This extreme sensitivity to processing conditions makes polymer engineering both a scientific challenge and a powerful design tool, enabling us to create materials with properties precisely tailored to desired functions.

Processing is often described as a “bridge” between polymer structure and properties. Synthesis determines the chemical composition and molecular structure of polymers, and the processing pathway determines how these molecular chains are combined into functional materials. In other words, the performance of the same polymer will be different due to its different molding, cooling, stretching, or curing methods. This process structure property relationship is particularly important for polymers because long-chain molecules of polymers are highly sensitive to thermal history, deformation, and flow. During processes such as extrusion, injection molding, compression molding, blow molding, and fiber spinning, the polymer undergoes melting, flow, and solidification, all of which influence its molecular orientation, crystallinity, and morphology. These microstructural features strongly affect the final mechanical, thermal, optical, and dimensional properties of the product.

Processing conditions also govern important thermal transitions, especially the glass transition temperature (Tg) and the melting temperature (Tm). Rapid cooling or high shear rates can limit chain relaxation and crystal formation, leading to higher Tg, reduced crystallinity, and slightly lower Tm. In contrast, slow cooling, annealing, or stretching allows more ordered chain packing, producing larger or more perfect crystals that increase Tm and improve thermal stability.

For researchers and engineers, understanding these relationships is essential to address major scientific and industrial challenges. From biomedical equipment and flexible electronic products to lightweight composites and sustainable packaging, the demand for materials with highly specific and adjustable properties is growing rapidly. This precision depends not only on the design of the polymer, but also on the ability to control molecular orientation, crystallinity, phase separation and morphology during processing. In addition, as the field moves towards sustainable development, mastering the manufacturing process is essential for achieving recyclable materials, solvent-free manufacturing and energy-saving production. Therefore, it is important for researchers to have an in-depth understanding of the processing technology, which transforms polymer science from a pure chemistry discipline to a set of applied engineering tools.

Scope:

Chapter 1: Fundamentals of Polymer Processing and Structure-Property Relationships

Introduces the basic physical principles of polymer processing, including viscosity, viscoelasticity, and heat transfer. Explains how parameters such as temperature, shear rate, and cooling rate influence molecular orientation, crystallinity, and thermal transitions like Tg and Tm.

Chapter 2: Common Fabrication Techniques and corresponding effects

Study widely used polymer processing methods such as extrusion, injection molding, compression molding, and fiber spinning, and explore how different flow and cooling conditions affect microstructure formation and material properties.

Chapter 3: Processing Effects on Thermal and Mechanical Behavior

Explore how processing affects key thermal transitions (Tg, Tm) as well as mechanical properties such as modulus, toughness, and dimensional stability. Strategies for tailoring properties through process optimization are highlighted.

Learning Outcomes:

- Explain the fundamental principles of common polymer fabrication processes, including extrusion, injection molding, compression molding, blow molding, and fiber spinning.

- Identify how each process influences the resulting polymer microstructure and properties.

- Correlate key processing parameters (such as temperature, shear rate, pressure, and cooling rate) with changes in molecular orientation, crystallinity, and morphology that determine mechanical, thermal, and optical behaviors of polymers.

- Analyze how different processing histories lead to variations in properties such as stiffness, toughness, clarity, and dimensional stability.

- Compare the structure–property outcomes among thermoplastic and thermosetting polymers fabricated by various methods, highlighting the role of crosslinking and flow behavior during processing.

- Evaluate common defects and residual stresses arising from improper processing conditions and explain how they affect product performance and reliability.