Few nonchemists know exactly what an epoxide is, but practically everyone has used an “epoxy glue” for household repairs or an epoxy resin for a protective coating. Worldwide, approximately 14 billion dollars’ worth of epoxy resins and adhesives are used annually for a vast number of applications, including many in the aerospace industry. Much of the Boeing 787 Dreamliner, for instance, is held together with epoxy-based adhesives.

Epoxy resins and adhesives generally consist of two components that are mixed just prior to use. One component is a liquid “prepolymer,” and the second is a “curing agent” that reacts with the prepolymer and causes it to solidify.

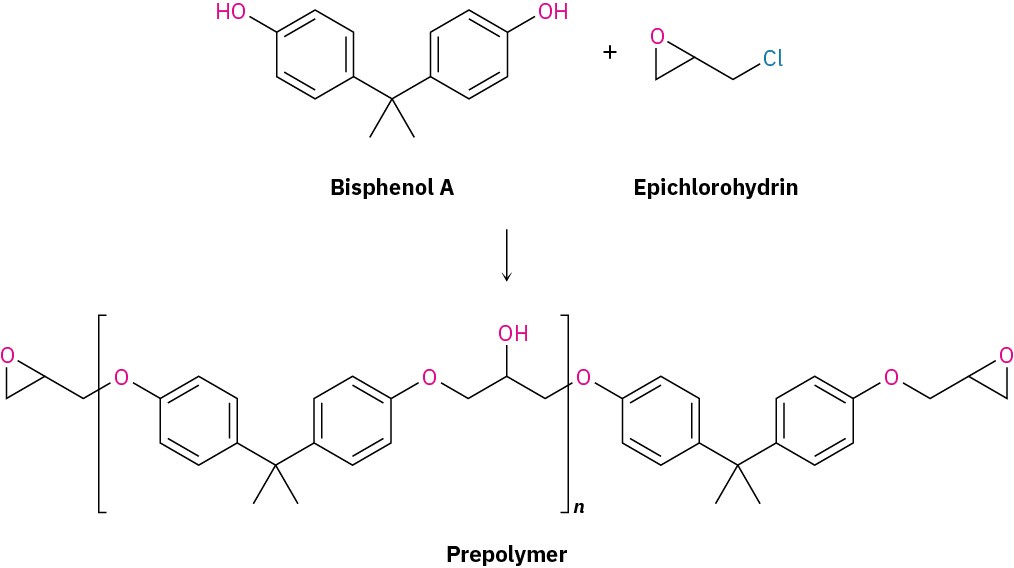

The most widely used epoxy resins and adhesives are based on a prepolymer made from bisphenol A and epichlorohydrin. On treatment with base, bisphenol A is converted into its anion, which acts as a nucleophile in an SN2 reaction with epichlorohydrin. Each epichlorohydrin molecule can react with two molecules of bisphenol A, once by SN2 displacement of chloride ion and once by nucleophilic opening of the epoxide ring. At the same time, each bisphenol A molecule can react with two epichlorohydrins, leading to a long polymer chain. Each end of a prepolymer chain has an unreacted epoxy group, and each chain has numerous secondary alcohol groups spaced regularly along its midsection.

Figure 18.7 Kayaks are often made of a high-strength polymer coated with epoxy resin. (credit: “Potomac River Festival Virginia 2017 Great Falls Kayak Race” by Watts/Flickr, CC BY 2.0)

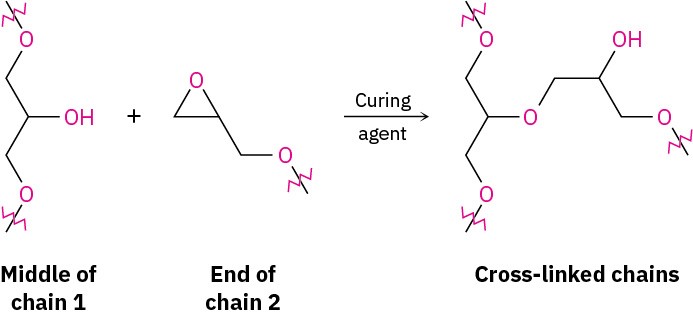

When an epoxide is to be used, a basic curing agent such as a tertiary amine, R3N, is added to cause the individual prepolymer chains to link together. This cross-linking of chains is simply a base-catalyzed, SN2 epoxide ring-opening of an –OH group in the middle of one chain with an epoxide group on the end of another chain. The result of such cross-linking is formation of a vast, three-dimensional tangle that has enormous strength and chemical resistance.