Liquids made of ions? Usually when we think of ionic compounds, we think of high-melting solids: sodium chloride, magnesium sulfate, lithium carbonate, and so forth. But yes, there are also ionic compounds that are liquid at room temperature, and they are gaining importance as reaction solvents, particularly for use in green chemistry processes (see the Chapter 11 Chemistry Matters). More than 1500 ionic liquids are known, and about 500 are available commercially.

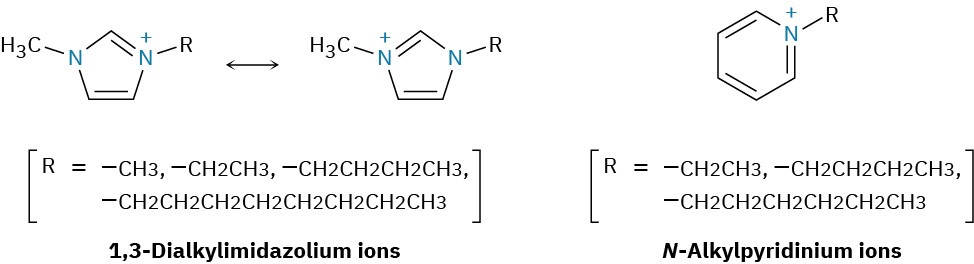

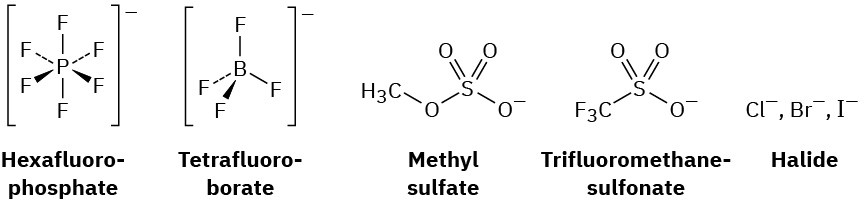

Ionic liquids have been studied for nearly a century; the first to be discovered was ethylammonium nitrate, CH3CH2NH3+ NO3–, with a melting point of 12 °C. More generally, however, the ionic liquids in use today are salts in which the cation is unsymmetrical and in which one or both of the ions are bulky so that the charges are dispersed over a large volume. Both factors minimize the crystal lattice energy and disfavor formation of the solid. Typical cations are quaternary ammonium ions from heterocyclic amines, either 1,3-dialkylimidazolium ions, N-alkylpyridinium ions, or ring-substituted N-alkylpyridinium ions.

Anions are just as varied as the cations. Hexafluorophosphate, tetrafluoroborate, alkyl sulfates, trifluoromethanesulfonates (triflates), and halides are some anion possibilities.

Ionic liquids have several important features that make them attractive for use, both as solvents in green chemistry and as specialty chemicals in such applications as paint additives and refrigerants:

- They dissolve both polar and nonpolar organic compounds, giving high solute concentrations and thereby minimizing the amount of solvent needed.

- They can be optimized for specific reactions by varying cation and anion structures.

- They are nonflammable.

- They are thermally stable.

- They have negligible vapor pressures and do not evaporate.

- They are generally recoverable and can be reused many times.

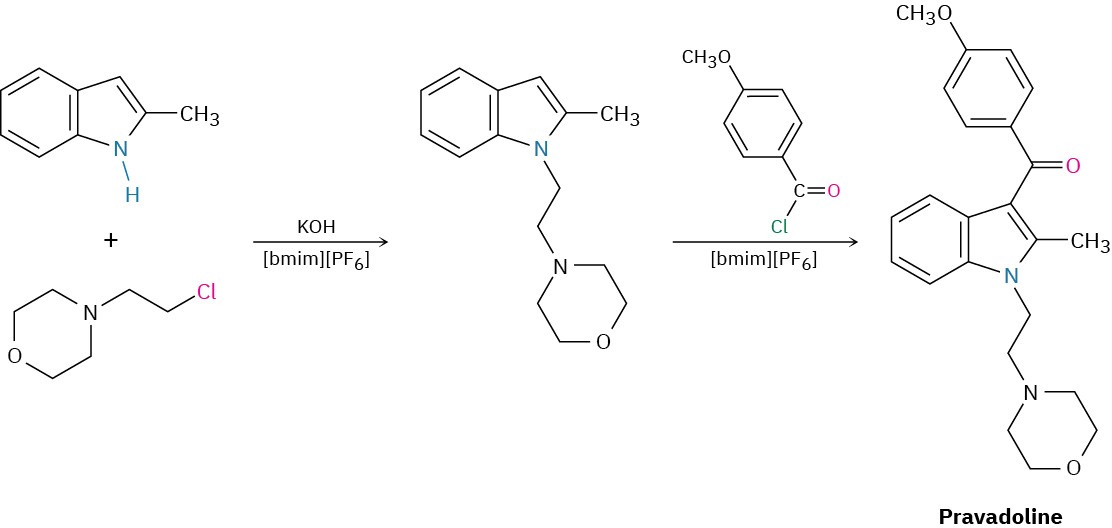

As an example of their use in organic chemistry, the analgesic drug pravadoline has been synthesized in two steps using 1-butyl-3-methylimidazolium hexafluorophosphate, abbreviated [bmim][PF6], as the solvent for both steps. The first step is a base-induced SN2 reaction of 2-methylindole with a primary alkyl halide, and the second is a Friedel–Crafts acylation. Both steps take place with 95% yield, and the ionic solvent is recovered simply by washing the reaction mixture, first with toluene and then with water.

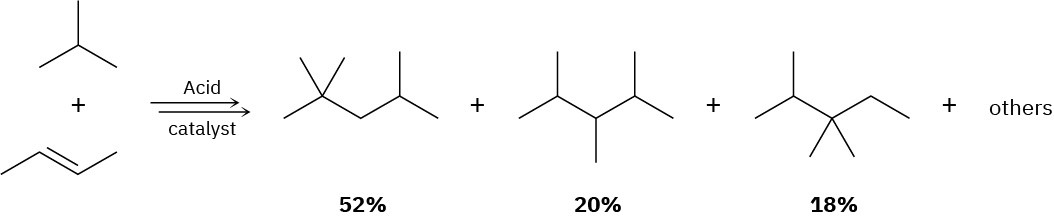

The first commercial process using an ionic liquid catalyst was introduced by PetroChina in 2008, when they opened a plant producing 65,000 tons per year of alkylate gasoline from isobutane. The aluminum-based ionic liquid catalyst replaced the sulfuric acid and hydrofluoric acid catalysts that had previously been used.