25 Polymer Information

Polymers used in Regenerative Medicine

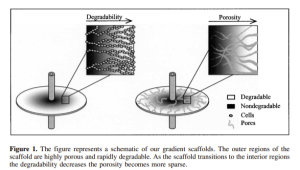

A typical polymer used for biomaterial applications is Poly-L-lactic acid (PLLA) and Poly-lactic-co-glycolic acid (PLGA). These polymers are chosen due to their mechanical properties, biocompatibility and ability to biodegrade. When used for a scaffold application, the device will begin mimicking a non degradable scaffold but over time it will slowly degrade. These degradable scaffolds provide transient support while the body is healing but then disappear, allowing for healthy tissue to replace the scaffold and for the body to regain its original function. This absence of a foreign material over time makes these polymer types ideal for scaffolds used in tissue engineering as it allows for the body to heal. The paper reviews these two polymers in application to a scaffold type that has both degradable and non degradable regions of the scaffold, designed as a gradient. The degradable region is highly porous, allowing for high levels of cell infiltration and tissue growth. This region is the outer portion of the scaffold. The non degradable region is infiltrated by the tissue growth promoted by the outer degradable region. This region will create an interlocking network between the tissue and the scaffold.

Chemical Structure

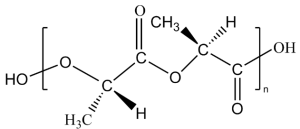

Poly L-lactic acid (PLLA) and Poly-lactic-co-glycolic acid (PLGA) are products of the Polylactic acid (PLA) family. This family of polymers is a synthetic, hydrophobic, aliphatic polyester that comes from lactic acid. There are multiple variations of PLA that exist including, PLLA, PDLA, and PDLLA. The distinguishing factor between these polymer types is the orientation of the molecules. Within the molecular structure of lactic acid there are both L-lactic acid and D-lactic acid optical isomers. When these two isomer types are mixed, DL-lactic acid can be produced. The resultant PLA type is dependent on these isomers.

Therefore, the processing type of the PLA will determine the resultant isomer type that is produced. PLLA is produced through the polymerization of L-lactic acid. It is a thermoplastic polyester material. This polymer type has the ability to degrade through hydrolysis within its environment over a period of time producing a byproduct of lactic acid.

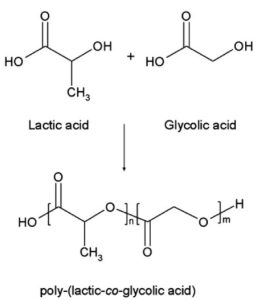

Poly(lactic-co-glycolic acid) (PLGA) is a copolymer composed of Poly-lactic acid (PLA) and Poly-glycolic acid (PGA). This is a linear copolymer that is created through the polymerization of both lactic acid and glycolic acid. These two were combined due to their individual biocompatibilities and degradation rates. Through controlling the processing of this copolymer, the resultant properties can be tailored based on the application. These properties include hydrophobic/hydrophilic balance, crystallinity and more.

Physical and Chemical Properties

The selected polymers, Poly-L-lactic acid (PLLA) and Poly(lactic-co-glycolic-acid) (PLGA), are widely used in biomaterial applications due to their good mechanical properties, biodegradable nature and biocompatibility.

PLLA is a semi-crystalline polymer, this crystallinity influences the resultant strength, stiffness and degradation time of the material. PLLA is also very chemically stable, meaning it will resist degradation by enzymes within the body and maintain its structure. This semi-crystalline structure and chemical stability makes this polymer type a good option for a biomaterial application. This is because the polymer has adequate mechanical properties to provide the necessary support within the body while the scaffold is aiding in the healing process. It will provide this support for a period of time more than necessary for the body to heal and then degrade into it’s non-toxic byproducts. Additionally, PLLA is a hydrophobic polymer which will extend the rate of degradation by hydrolysis. PLLA that has a higher molecular weight is the optimal choice for applications such as tissue scaffolds or stents as the degradation rate is slower and the mechanical properties of the device are better retained over time.

PLGA is an amorphous co-polymer made of PLA and PGA. The benefit of using this polymer for biomaterial applications is that the properties can be tailored through adjusting the ratio of hydrophobic PLA to hydrophilic PGA depending on the application. Increasing the amount of PLA will decrease the degradation rate due to the hydrophobic nature and inversely increasing the amount of PGA will increase the degradation rate due to the hydrophilic nature of PGA. The more hydrophobic a polymer is, the rapidly the structure will be infiltrated and the bonds will break, causing degradation. The mechanical properties of PLGA can be increased through increasing the level of PGA as well.

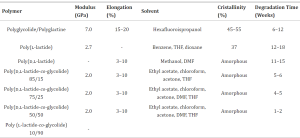

A comparison of PLLA and PLGA can be seen in the table below in terms of strength, crystallinity and degradation time. The relationship between crystallinity and degradation rates is observed when comparing the PLLA and the PLGA %crystallinity and degradation times. Therefore, PLLA is a better polymer for applications where a longer duration of material presence is desired while PLGA offers more flexibility in terms of degradation and mechanical properties, allowing it to be more tailorable by application. Due to this, it was seen in the reviewed paper, “Tissue Engineering and the Challenges Within,” that the scaffold made of PLGA had a greater amount of cellular infiltration within the degradable portion as well as ECM proteins.

Selection and Benefits

The benefits of selecting PLLA for tissue engineering applications include:

- Mechanical Properties:

- PLLA has excellent mechanical properties for it’s application. It is one of the only polymers that will provide the necessary mechanical support over longer regenerative processes. Its mechanical properties are also tailorable through controlling the polymer properties such as molecular weight, crystallinity and aging characteristics.

- Biodegradability:

- PLLA degrades through hydrolysis, resulting in a byproduct of lactic acid. This is naturally metabolized by the body and therefore non-toxic. This characteristic makes it a great option for scaffolds within tissue engineering applications as it will degrade and leave the body in its natural state.

- Biocompatibility:

- PLLA is a FDA approved polymer for use in biomaterials. It’s degradation byproducts are non-toxic to the body and therefore this polymer has a wide range of use for both degradable and non degradable applications.

- Surface Modification Potential:

- The surface characteristics of PLLA can be modified to enhance cellular attachment and proliferation. This enhancement will promote the tissue regrowth and integration of the scaffold into the biological system.

The benefits of selecting PLGA for tissue engineering applications include:

- Monomer Ratio:

- PLGA is a copolymer made of a PLA/PGA blend. Through the alteration of this polymer to polymer ratio the properties can be changed. These properties include strength, degradation rate, surface characteristics and more.

- Biocompatibility:

- PLGA is a biocompatible polymer, consisting of two FDA approved polymers for use in biomaterials. Its degradation byproducts are non-toxic to the body and therefore this polymer has a wide range of use for both degradable and non degradable applications.

- Biodegradability Rate:

- The rate of degradation can be increased or decreased through the ratio of PGA to PLA and molecular weight. This allows for controlled resorption times.

- Surface Modification potential:

- Through changing the ratio of hydrophilic PGA to hydrophobic PLA with the PLGA copolymer, the surface characteristics of the polymer can be controlled.

In summary, PLLA and PLGA stand as versatile and crucial materials in regenerative medicine, offering tailored support for tissue regeneration and restoration. Their distinct properties and tunability make them indispensable in scaffold applications, fostering natural healing processes while minimizing foreign body presence.

Media Attributions

- Gradient Scaffold

- PLA and isomers

- PLLA

- PLGA synthesis

- Polymer Type and Properties