36 Discussion

Analysis of the Polymer(s) in Context

The polymer types PLLA and PLGA both have a large presence in the world of biomaterials. This is due to their mechanical properties, biocompatibility and biodegradability. These properties also have the ability to be tailored depending on application in terms of their molecular weight, crystallinity, monomer ratio (PLGA) and surface characteristics, making them even more significant in application to biomaterials.

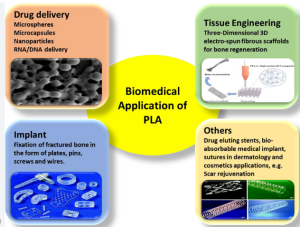

The polymer, PLLA, can be seen in biomaterial applications that include drug delivery, implants, and sutures in addition to tissue engineering. This polymer is derived from lactic acid, which can be obtained from the fermentation of sugars from a renewable resource like corn or sugarcane. Therefore it is widely accessible, environmentally friendly and readily available for use in a variety of applications. When designing a biomaterial it is most important to observe the biocompatibility, mechanical properties, and biodegradability of the material. Through extensive in vitro testing of structures made of PLLA, it can be determined that the polymer is generally biocompatible and has gained FDA approval for medical use. This approval expands its scope of use within the biomaterial world as it has already been verified as a biocompatible option. In terms of PLLA’s degradation and mechanical properties, these can be tailored based on application through polymer processing techniques. This tailorability of relevant biomaterial properties also make it more popular for use within the world of biomaterials and widens the range of what this polymer can be used for. For example, the mechanical strength can be increased when the polymer is being used for an application such as implants or scaffolding through an increase in the molecular weight of the polymer. Another advantage of PLLA is that it has the ability to be combined with other polymer types to create a copolymer with the most desirable properties. While the advantage of tailorable properties does push PLLA forward in the world of biomaterials, there are some limitations of this polymer type. These include degradation rate and brittleness. While a longer degradation rate is desired for some applications, it can be a negative characteristic in others. Due to the chemical stability and high crystallinity of the PLLA structure, it has the tendency to take longer to fully degrade within its environment in comparison to other polymer types. Additionally, due to this high crystalline structure, the PLLA biomaterial can sometimes be brittle in nature which will influence certain mechanical properties.

The combination of hydrophobic PLA and hydrophilic PGA came to form PLGA and optimize the desired degradation rates and surface characteristics. A major application of PLGA in the world of biomaterials is for nanomedicine and bone engineering, in addition to tissue engineering. This polymer type is desired in biomaterials due to the ability to manipulate the ratio of PLA monomer to PGA monomer. The manipulation of this ratio can control the degradation rate, molecular weight, hydrophobicity, crystallinity and mechanical properties. All of which are the most relevant properties when it comes to biomaterial selection. The PGA component is a crystalline hydrophilic polymer while the PLA is a stiff hydrophobic polymer. Through manipulating this hydrophobicity of the biomaterial, the degradation rate can be controlled. Therefore, this is a great option for nanomedicine applications where the drug delivery rate needs to be specified. The limitations associated with PLGA include long term stability, and hydrophobicity. The copolymer has the tendency to degrade at a faster rate in comparison to its alternatives, this is not suitable for some applications and the polymers loses its mechanical properties quicker due to this as well. Depending on the application, the hydrophilic nature of PGA is often desired, however since PLA is present the copolymer is inherently hydrophobic which is not always suitable for all biomaterial applications.