26 Characterization Techniques

Characterization Techniques Overview

X-Ray Diffraction (XRD)

XRD is a powerful analytical method used to examine various physical properties of materials, such as their crystalline structure and composition. Essentially, it works by analyzing how x-rays interact with the atomic arrangement within a sample.

Polymers are often composed of small crystalline units known as crystallites, each with its own unique structure called a “phase”. These phases can vary, and materials can contain single or multiple phases, along with non-crystalline components. In an XRD analysis, different phases produce distinct diffraction patterns, similar to identifying unique fingerprints in a crime investigation.

To identify these phases, scientists compare the diffraction patterns of unknown samples to those stored in reference databases, such as the comprehensive database maintained by the International Center of Diffraction Data (ICDD). Additionally, researchers can create their own reference databases using pure-phase patterns measured in the laboratory or obtained from scientific literature.

An XRD instrument typically consists of three main components: an x-ray source, a sample holder, and a detector. X-rays emitted by the source illuminate the sample, and the diffracted x-rays are captured by the detector. By adjusting the angle at which the x-rays strike the sample and measuring the intensity of the diffracted x-rays, scientists can gather valuable data about the sample’s structure and composition.

XRD offers several advantages, including speed, minimal sample preparation, and high accuracy, making it a valuable tool for both industrial and research applications. Automated analysis further enhances its utility, particularly in quality control processes where expert knowledge is not always required. XRD does have some limitations such as not being able to identify amorphous materials, no depth profile information, and minimum spot size of ~25 µm.

Transmission Electron Microscopy (TEM)

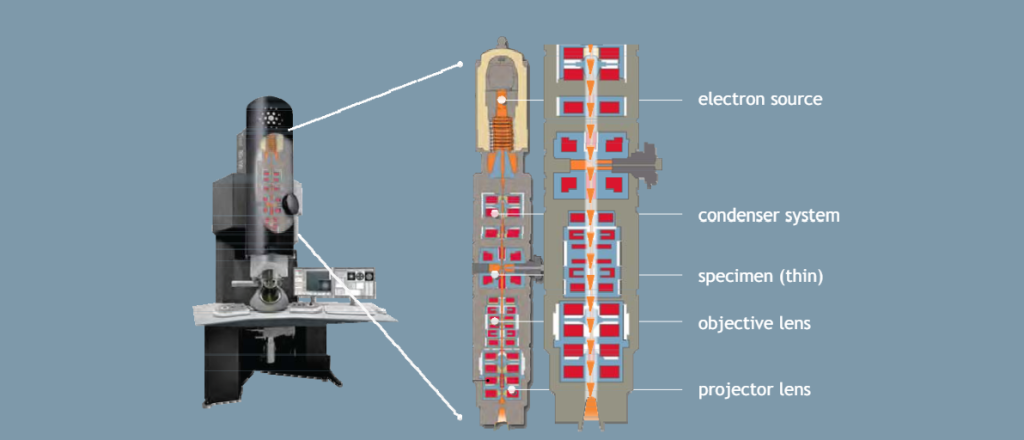

TEM is a powerful tool used to visualize the smallest structures within materials at the atomic scale. Unlike traditional optical microscopes that use visible light, TEM utilizes electron beams to achieve incredibly high magnifications, up to 50 million times. This is possible because electrons have much shorter wavelengths than visible light when accelerated through strong electromagnetic fields, resulting in significantly improved resolution.

To create a TEM image, a high-energy electron beam is passed through an extremely thin sample, typically less than 100 nanometers thick. Electromagnetic lenses within the microscope focus the beam onto the sample and magnify the resulting image onto a screen or camera.

TEM instruments come in various forms, with the two main types being conventional TEM and scanning transmission electron microscopy (STEM). TEM instruments consist of several key components including an electron gun, vacuum system, microscope column, detectors, and control computers. The electron gun produces the electron beam, which is focused onto the sample by the microscope column’s electromagnetic lenses. Detectors capture the resulting images or diffraction patterns for analysis. TEM operates under high vacuum conditions to eliminate interactions between the electron beam and other substances. Sample preparation involves creating extremely thin specimens, which can be challenging but is essential for achieving high-resolution imaging.

Some advantages of TEM include that it offers the highest and most powerful magnification of any microscopy technique, it has versatile imaging modes, it provides the ability to collect electron diffraction patterns, and it enables nano-analysis which is the ability to collect local information about composition and bonding which can be correlated to high resolution images. TEM also has some limitations such as limited sampling area, complex image interpretation, potential electron beam damage to samples, and the requirement for a vacuum environment.

Information Provided by the Technique

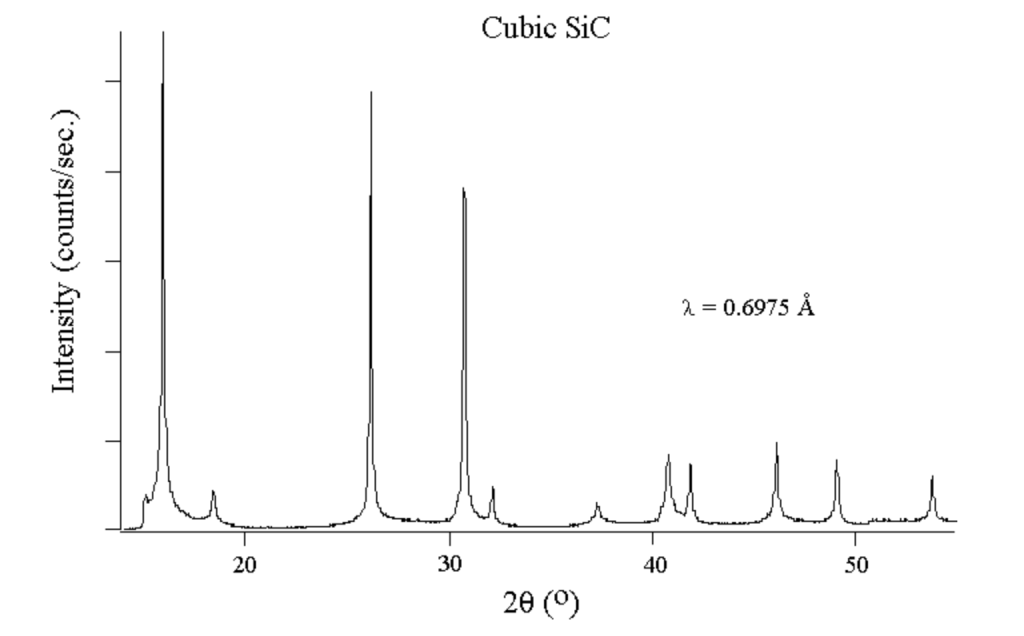

XRD produces plots showing the intensity of signals at different diffraction angles, known as two tehta positions. These positions correspond to the spacing between crystals or atoms in the sample, determined by the angle of diffraction from the x-ray beam. The intensity of the peaks indicates the amount of molecules with that particular spacing. Higher peak intensity suggests a greater quantity of crystals or molecules with that specific spacing.

The width of the peaks is inversely related to the crystal size. A narrower peak indicates larger crystals, while a broader peak may suggest smaller crystals, defects in crystal structure, or an amorphous sample lacking perfect crystallinity. XRD analysis can help determine the composition of smaller samples by comparing their patterns to a vast database of known elements, compounds, and minerals. By matching the diffraction patterns, including their location, width, and relative heights, researchers can verify the identity of unknown compounds.

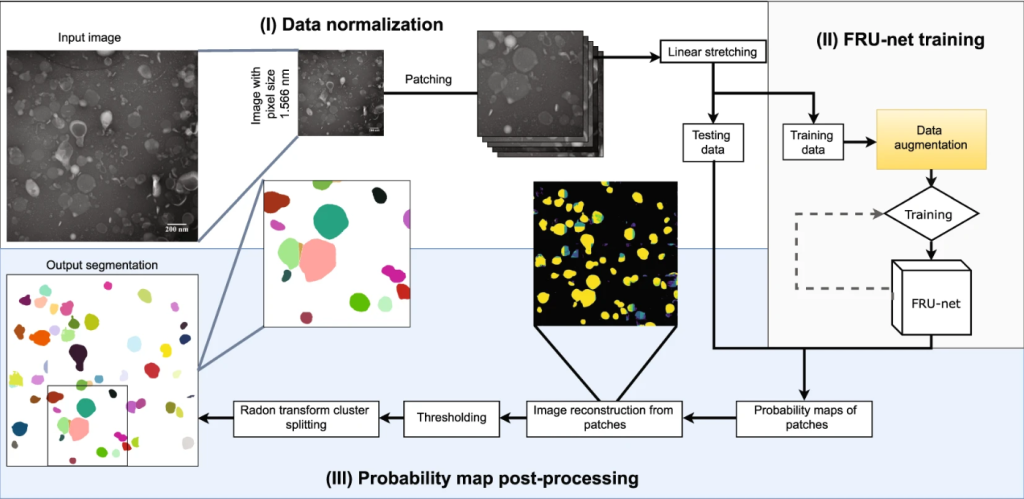

One of the limitations of TEM is that the data is slightly harder to analyze. After passing through the sample, the incident electrons in a TEM interact with its atoms, altering their energy and trajectory. These interactions vary depending on the structure present. As a result, TEM images provide insights into the internal structure of the sample. However, due to the complexity of both the sample and the interactions, the resulting images are intricate and not as immediately comprehensible as surface topography.

TEM data analysis involves processing data to extract information about the sample’s structure through measurements, analysis, and calibrations of the original spectrum. This analysis yields details such as sample size, particle size distribution, crystal grain size, crystal structure, composition of crystal phases, and atomic arrangement.

Importance of the Technology

XRD plays a significant role in advancing regenerative medicine and tissue engineering by providing insights into the structural properties of biomaterials and tissue constructs. It allows researchers to analyze the crystalline structure of biomaterials used in tissue engineering, such as scaffolds and hydrogels. By examining the diffraction patterns of these materials, scientists can determine their crystallographic properties, phase composition, and atomic arrangements. This information is essential for optimizing the design and synthesis of biomaterials with desired mechanical, chemical, and biological properties. Researchers can also use XRD data to assess the similarity in tissue composition and structure which helps validate tissue engineering approaches and refine fabrication techniques to better mimic the properties of native tissues. Additionally, XRD studies can provide insights into how cells interact with biomaterials at the molecular level. By analyzing changes in the crystalline structure of biomaterials in response to cellular activity, researchers can see the cellular mechanisms involved in tissue regeneration and repair. This understanding informs the design of biomaterials that promote favorable cellular responses and tissue integration in regenerative medicine applications.

TEM can also significantly enhance the understanding and development of regenerative medicine and tissue engineering through its ability to provide high-resolution imaging and detailed structural analysis at the nanoscale. It allows researchers to visualize the ultrastructure of cells, tissues, and extracellular matrices with exceptional detail. This includes observing organelles, cell-cell interactions, extracellular matrix components, and tissue architecture at the nanometer scale. By examining the morphology and organization of cellular and extracellular structures, researchers gain insights into tissue development, organization, and functionality. TEM also enables the characterization of biomaterials and tissue-engineered scaffolds at the nanoscale level. Researchers can examine the porosity, surface features, and distribution of nanoparticles or biomolecules within the scaffolds. This information is crucial for assessing scaffold quality, optimizing fabrication techniques, and designing biomaterials with tailored properties for tissue regenerations.

Media Attributions

- University of California Museum of Paleontology, Understanding Science

- Biomaterial Surfaces: Characterization

- X-ray diffraction (XRD) basics and application

- TEM data analysis