Online Course Improvement Program (OCIP)

Since I recently completed the DELTA-sponsored Quality Matters Online Teaching Certificate (QM OTC), I was asked to apply for DELTA’s Online Course Improvement Program (OCIP) and was accepted. Note, OCIP was restructured and is now a year long and called the Course Improvement Grant. Since my scholarly reassignment was focused on developing interactive, online content for both my students and outreach; I was excited about joining OCIP, as this seemed a logical extension to what I already had planned (and I would be regularly interreacting with DELTA experts who could help with trouble shooting H5P content, which proved to be a huge bonus!).

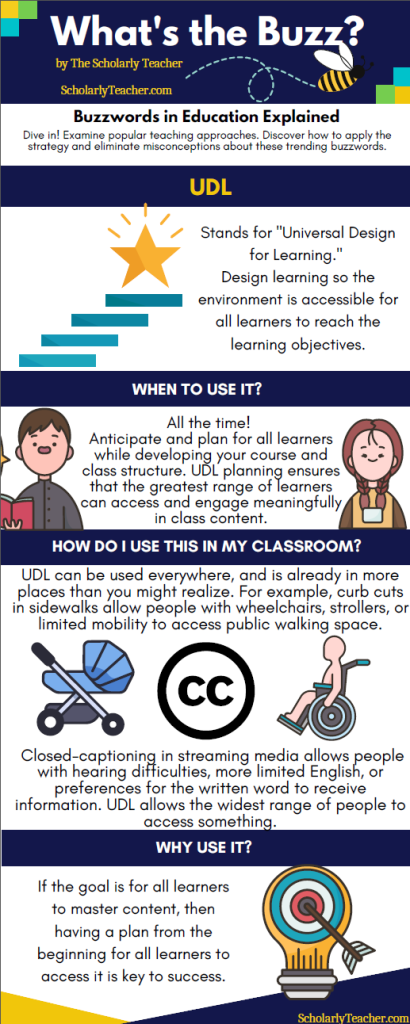

As part of the program, I made huge improvements to the TE 200 Moodle page, started implementing Universal Design for Learning Principles (see Figure 1), and really put the skills I learned completing the QM OTC to good use. As an example of what I was creating during OCIP, I have shared my module learning outcomes (MOs) and how they map to course learning outcomes (and what I call study guide questions (SG) for my course, Introduction to Polymer Science & Engineering (TE 200).

Module Learning Outcomes Mapped to Course LOs for Introduction to Polymer Science & Engineering (TE 200)

The student learning outcomes for the course (aka course outcomes or COs) are what students are expected to know by the end of the course. To achieve these COs, the course was broken into smaller “modules” and each module has specific learning objectives (aka module objectives or MOs). Every MO supports one or more COs, by design. And in order to determine if we are meeting our learning objectives, every MO is assessed in some manner (this could be part of low or no stakes assessments or high stakes assessments).

To support student success in the learning objectives, study guides were developed for each module. These “study guide questions” or SGs strongly overlap with the MOs, but might be more fundamental (i.e., define polymer or amorphous) or might be more specific or detailed than the MOs. Take CO I for example; two MOs (MO 1.1 and MO 1.2) support CO I. MO 1.1 is a study guide question (SG) and it has a second SG supporting it that is very fundamental (define a bunch of polymer related terms). This SG is helpful to the students, because it shares the words they will need to describe polymers. Since it is building up to the more important goal of MO 1.1 and is not directly assessed, it is a study guide question, not a module objective (it is too fundamental and too specific to be an MO). In addition, MO 1.2 is not in the study guide verbatim. It has been replaced with two SG questions that are more detailed and specific (they are written to guide the students to meet MO 1.2). These are not included as MOs, because that would require detailed and time consuming assessments and result in ridiculously long exams. For example, the SG question that states “Explain how and why polymers are unique compared to small molecules, in terms of: molecular entanglements, summation of intermolecular forces, and time scale of motion.” tells the students my exact expectations for explaining the uniqueness of polymers, but would require assessment on 1) molecular entanglements, 2) summation of intermolecular forces, and 3) time scale of motion. Typically, students are asked about one of those three on the first exam–not all three.

Student Learning Outcomes (aka Course LOs or COs):

Upon successful completion of this course, a student should be able to:

I. Describe the importance of polymers, including some of their many uses, and how they differ from small molecules.

II. Describe and discuss polymer structure, microstructure, morphology, and conformations.

III. Explain basic structure-property relationships.

IV. Define, calculate, and estimate molecular weight, polydispersity, degree of polymerization, and extent of reaction.

V. Complete step growth and chain growth polymerization reactions and determine what mechanism was used to produce a given polymer.

VI. Solve kinetics problems and derive straightforward kinetics equations using standard assumptions and rate laws for step and chain growth polymerizations.

VII. Describe the significance of polymer thermal transitions.

Module Learning Outcomes (MOs) & Module Study Guide (SG) Questions Mapped to the COs

I. Describe the importance of polymers, including some of their many uses, and how they differ from small molecules.

MO 1.1 Describe polymers, their importance, and their many uses. (SG M02)

SG M01 Define: polymer, macromolecule, monomer, repeat unit, degree of polymerization, homopolymer, copolymer, blend, thermoset, and thermoplastic.

MO 1.2 Explain how and why polymers are unique compared to small molecules.

SG M01 Explain, typically by using an analogy, how big/long polymers are, as compared to solvents/monomers/other small molecules.

SG M01 Explain how and why polymers are unique compared to small molecules, in terms of: molecular entanglements, summation of intermolecular forces, and time scale of motion.

MO 9.1 Explain how polymers’ melt/crystallization behavior is different from typical small molecules.

SG 09 Define and explain the following as they relate to polymers: crystallization temperature, melting temperature, glass transition temperature, and free volume.

SG 09 Briefly explain why the melting and crystallization temperatures are usually not the same temperature for polymers.

SG 09 Briefly explain why polymers often melt over a range of temperatures.

II. Describe and discuss polymer structure, microstructure, morphology, and conformations.

MO 1.2 Explain how and why polymers are unique compared to small molecules.

MO 2.1 Describe different types of polymer structures (e.g., linear, branched, star, etc.).

SG M02 Explain the difference between a side group and a branch.

MO 2.3 Explain network polymers and the two primary ways they are formed. (SG M02)

MO 2.4 Explain the impact of cross-linking and the cross-link density on polymer properties. (SG M02)

MO 2.5 Identify the different isomeric forms found in polymer chains (i.e., sequence, stereo, and structural isomerism).

SG M02 Explain sequence isomerism.

SG M02 Identify stereo-isomerism (tacticity) in vinyl polymers, including atactic, isotactic, and syndiotactic.

SG M02 Explain structural isomerism in diene polymers and how that can impact properties.

MO 2.6 Identify the four primary types of copolymers. (SG M02)

MO 2.7 Describe how structure and microstructure impact a polymer’s ability to crystallize.

SG M02 Explain the impact of branching on a polymer’s ability to crystallize.

SG M02 Explain the impact of tacticity on polymer properties, specifically a polymer’s ability to crystallize.

SG M08 Define and/or describe the following as they relate to polymers: morphology, fringed micelle, lamella, spherulite, row nucleated structures, conformations, end-to-end distance, tie molecules.

MO 8.1 Explain polymer conformations, including how many conformations are possible. (SG M08)

SG M08 Recognize that if each bond in the backbone has X possible confirmations and Y bonds in the backbone, then there are XY possible conformations (ignoring redundancies). A student should be able to explain why it is multiplicative and not additive.

MO 8.3 Describe the morphology of common polymer crystal types.

SG M08 Describe the overall shape and form of polymer crystals, specifically: single crystals, spherulites, and row nucleated structures.

MO 8.5 Given a set of conditions, a student should be able to predict the morphology of the polymer.

III. Explain basic structure-property relationships.

MO 1.3/9.10 Describe an amorphous polymer.

SG M01/SG M09 Describe an amorphous polymer when it is: above its Tg and below its Tg.

MO 1.4/9.11 Describe a semi-crystalline polymer.

SG M01/SG M09 Describe a semi-crystalline polymer when it is: above its Tm and Tg, between its Tm and Tg, and below its Tm and Tg.

MO 2.2/MO 8.4 Describe how changing a polymer’s crystallinity affects its physical properties.

SG M01/SG M08 Describe how increasing or decreasing a polymer’s percent crystallinity affects the following properties: strength, stiffness, toughness, brittleness, optical clarity, barrier properties, and solubility.

MO 2.4 Explain the impact of cross-linking and the cross-link density on polymer properties.

MO 2.7 Describe how structure and microstructure impact a polymer’s ability to crystallize.

MO 3.1 Given a polymer structure, identify if the polymer likely was made by a step growth or chain growth polymerization.

MO 3.3 Given a step growth polymer structure, determine whether it was made in an A-B or A-A/B-B type polymerization.

MO 8.2 Explain how polymers’ properties impact their end-to-end distances.

SG M08 Explain how a polymer’s end-to-end distance changes with: solvent quality, molecular weight, and backbone stiffness.

MO 9.4 A student should be able to explain how different factors impact the melting temperature of a polymer.

SG 09 Explain how the following affect the melting temperature of a polymer: stiffness of the polymer backbone, molecular interactions, bulky side groups, diluents (e.g., solvents), co-monomers, and molecular weight.

SG 09 Given a series of polymers (with the structures provided), order them by increasing (or decreasing) melting temperature.

SG 09 Determine which polymer (structures given) has the higher melting temperature and explain how they came to that conclusion in one to two sentences.

MO 9.5 Explain how different factors impact the glass transition temperature of a polymer.

SG 09 Explain how the following affect the glass transition temperature of a polymer: stiffness of the polymer backbone, molecular interactions, bulky side groups, flexible side groups, diluents (e.g., solvents, plasticizers), molecular weight, degree of cross-linking, degree of crystallinity, and free volume.

SG 09 Given a series of polymers (with the structures provided), order them by increasing (or decreasing) glass transition temperature.

SG 09 Determine which polymer (structures given) has the higher glass transition temperature and explain how they came to that conclusion in one to two sentences.

IV. Define, calculate, and estimate molecular weight, polydispersity, degree of polymerization, and extent of reaction.

MO 4.1 Given the equation, calculate the number-average molecular weight. (SG M04)

MO 4.2 Given the equation, calculate the weight-average molecular weight. (SG M04)

MO 4.3 Calculate the number- and weight-average degree of polymerization.

SG M04 Calculate the number-average degree of polymerization.

SG M04 Calculate the weight-average degree of polymerization.

MO 4.4 Interpret a molecular weight distribution plot.

SG M04 Identify key aspects of a MW distribution plot (e.g., a narrow distribution versus a broad one, which curve has a higher Mn/Mw, etc.).

MO 4.5 Calculate and interpret polydispersity.

SG M04 Explain the importance of the polydispersity index.

SG M04 Calculate polydispersity.

MO 4.6 Use your knowledge of polydispersity to convert from weight average to number average, and vice versa. (SG M04)

MO 4.7 Given the appropriate equations, calculate the polydispersity, Xn and Xw from the extent of reaction (p) for step growth polymers (and vice versa). (SG M04)

SG M04 Explain why the polydispersity of step growth polymers is ca. 2.

V. Complete step growth and chain growth polymerization reactions and determine what mechanism was used to produce a given polymer.

MO 3.1 Given a polymer structure, identify if the polymer likely was made by a step growth or chain growth polymerization.

SG M03 Given a polymer structure, identify if the polymer likely was made by a step growth or chain growth polymerization and justify your identification in a sentence or two.

MO 3.3 Given a step growth polymer structure, determine whether it was made in an A-B or A-A/B-B type polymerization.

SG M03 Given a step growth polymer structure, determine whether it was made in an A-B or A-A/B-B type polymerization and justify your identification in a sentence or two.

MO 3.3 Compare and contrast step and chain growth polymerizations. (SG M03)

SG M03 Sketch and explain the differences in the plots of molecular weight (or degree of polymerization) versus extent of reaction for step and chain growth polymerizations.

MO 5.1 Given a step-growth polymer structure, determine what monomer or monomers it may have been made from.

SG M05 Given a step-growth polymer structure, determine what monomer or monomers it may have been made from (polyesters and polyamides, only).

MO 5.2 Complete step growth polymerization reactions; mechanisms are not required. (SG M05)

MO 5.3 Explain the impact of monofunctional impurities and stoichiometric inequality on step growth polymerizations. (SG M05)

MO 5.4 Explain the impact of polymerizing a monomer with a functionality other than 2. (SG M05)

MO 6.1 Given a chain growth polymer structure, determine what monomer or monomers it may have been made from. (SG M06)

MO 6.2 Complete polymerization reactions for chain growth monomers; mechanisms are not required. (SG M06)

MO 6.3 Given part of a chain growth reaction scheme, identify whether the reaction is initiation, propagation, or termination and what type of polymerization it is (free radical, anionic, cationic, coordination). (SG M06)

MO 6.4 Choose the best type of chain growth polymerization (free radical, anionic, cationic, coordination) for a given monomer or desired polymer characteristics. (SG M06)

MO 6.5 Explain what a living polymerization is and why it is important. (SG M06)

VI. Solve kinetics problems and derive straightforward kinetics equations using standard assumptions and rate laws for step and chain growth polymerizations.

MO 7.1 Step Growth Polymerization Kinetics

7.1.a Given an appropriate rate law, solve step-growth kinetics problems.

SG M07 General Kinetics: From the context of the problem, determine if it is a step growth or chain growth problem.

SG M07 General Kinetics: From the context of the problem, determine if integration must be used to solve the problem.

SG M07 General Kinetics: Determine what assumptions are relevant and appropriate to the given problem and then successfully apply the assumptions to solve the problem.

SG M07 Remember and appropriately use the fact that the concentration of acid groups equals the concentration of alcohol groups at all times.

SG M07 Given an appropriate rate law, solve for acid/alcohol concentration, extent of reaction, and number average degree of polymerization as a function of time or for some time, t (and vice versa).

SG M07 Given an appropriate rate law, determine how long it will take to reach a given concentration, extent of reaction, or number-average degree of polymerization.

7.1.b Discuss the importance of reactivity being independent of chain length. (SG M07)

MO 7.2 Chain Growth Polymerization Kinetics

7.2.a Given the appropriate rate laws, solve chain-growth kinetics problems, such as kinetic chain length or monomer concentration.

SG M07 General Kinetics: Solve a classic radioactive decay problem (because this is the same free radical initiation!).

SG M07 General Kinetics: From the context of the problem, determine if it is a step growth or chain growth problem.

SG M07 General Kinetics: From the context of the problem, determine if integration must be used to solve the problem.

SG M07 General Kinetics: Determine what assumptions are relevant and appropriate to the given problem and then successfully apply the assumptions to solve the problem.

SG M07 Apply initial conditions, when appropriate, to solve problems.

SG M07 Effectively use the steady state assumption and explain the assumption in words (including what is at steady state).

SG M07 Given appropriate rate laws, solve for monomer concentration as a function of time or for some time, t, and vice versa.

SG M07 Given appropriate rate laws, calculate the kinetic chain length.

7.2.b Calculate the number-average degree of polymerization from the kinetic chain length. (SG M07)

7.2.c Identify the Tromsdorf effect and its importance. (SG M07)

7.2.d Explain the steady state assumption in words (including what is at steady state).

VII. Describe the significance of polymer thermal transitions.

MO 1.3/9.6 Describe an amorphous polymer.

MO 1.4/9.7 Describe a semi-crystalline polymer.

MO 8.5 Given a set of conditions, a student should be able to predict the morphology of the polymer.

SG M08 Given a set of conditions, predict the morphology of the polymer. For example, if a crystallizable polymer is slowly cooled from the melt in a cooling dish, then one would predict the sample would crystallize forming spherulites.

MO 9.1 Explain how polymers’ melt/crystallization behavior is different from typical small molecules.

SG 09 Define and explain the following as they relate to polymers: crystallization temperature, melting temperature, glass transition temperature, and free volume.

SG 09 Briefly explain why the melting and crystallization temperatures are usually not the same temperature for polymers.

SG 09 Briefly explain why polymers often melt over a range of temperatures.

MO 9.2 Interpret a specific volume versus temperature plot.

SG 09 Given a specific volume versus temperature plot, a student should be able to identify (if present): the melting/crystallization transition, and the glass transition.

MO 9.3 A student should be able to explain how different heat/cooling treatments can impact polymer crystallization.

SG 09 Define under cooling (super cooling) as it relates to polymer crystallization and explain its importance.

SG 09 Define annealing as it relates to polymer crystallization and explain its importance.

MO 9.4 A student should be able to explain how different factors impact the melting temperature of a polymer.

SG 09 Explain how the following affect the melting temperature of a polymer: stiffness of the polymer backbone, molecular interactions, bulky side groups, diluents (e.g., solvents), co-monomers, and molecular weight.

SG 09 Given a series of polymers (with the structures provided), order them by increasing (or decreasing) melting temperature.

SG 09 Determine which polymer (structures given) has the higher melting temperature and explain how they came to that conclusion in one to two sentences.

MO 9.5 Explain how different factors impact the glass transition temperature of a polymer.

SG 09 Explain how the following affect the glass transition temperature of a polymer: stiffness of the polymer backbone, molecular interactions, bulky side groups, flexible side groups, diluents (e.g., solvents, plasticizers), molecular weight, degree of cross-linking, degree of crystallinity, and free volume.

MO 9.8 Given a series of polymers (with the structures provided), order them by increasing (or decreasing) glass transition temperature. (SG 09)

MO 9.9 Determine which polymer (structures given) has the higher glass transition temperature and explain how they came to that conclusion in one to two sentences. (SG 09)