Chemistry Matters — Gasoline

British Foreign Minister Ernest Bevin once said that “The Kingdom of Heaven runs on righteousness, but the Kingdom of Earth runs on alkanes.” (Actually, he said “runs on oil” not “runs on alkanes,” but they’re essentially the same.) By far, the major sources of alkanes are the world’s natural gas and petroleum deposits. Laid down eons ago, these deposits are thought to be derived primarily from the decomposition of tiny single-celled marine organisms called foraminifera. Natural gas consists chiefly of methane but also contains ethane, propane, and butane. Petroleum is a complex mixture of hydrocarbons that must be separated into fractions and then further refined before it can be used.

Figure 2.26 Gasoline is a finite resource. It won’t be around forever. (credit: “The first oil well” by Unknown/Library of Congress)

Figure 2.26 Gasoline is a finite resource. It won’t be around forever. (credit: “The first oil well” by Unknown/Library of Congress)

The petroleum era began in August 1859, when the world’s first oil well was drilled by Edwin Drake near Titusville, Pennsylvania. The petroleum was distilled into fractions according to boiling point, but it was high-boiling kerosene, or lamp oil, rather than gasoline that was primarily sought. Literacy was becoming widespread at the time, and people wanted better light for reading than was available from candles. Gasoline was too volatile for use in lamps and was initially considered a waste by-product. The world has changed greatly since those early days, however, and it is now gasoline rather than lamp oil that is prized.

Petroleum refining begins by fractional distillation of crude oil into three principal cuts according to boiling point (bp): straight-run gasoline (bp 30–200 °C), kerosene (bp 175– 300 °C), and heating oil, or diesel fuel (bp 275–400 °C). Further distillation under reduced pressure then yields lubricating oils and waxes and leaves a tarry residue of asphalt. The distillation of crude oil is only the first step in gasoline production, however. Straight-run gasoline turns out to be a poor fuel in automobiles because of engine knock, an uncontrolled combustion that can occur in a hot engine causing potentially serious damage.

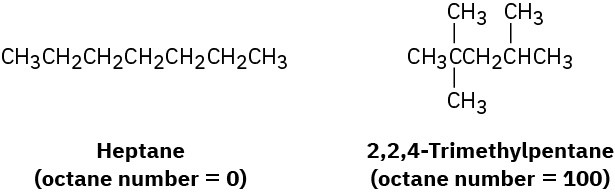

The octane number of a fuel is the measure by which its antiknock properties are judged. It was recognized long ago that straight-chain hydrocarbons are far more prone to inducing engine knock than highly branched compounds. Heptane, a particularly bad fuel, is assigned a base value of 0 octane number, and 2,2,4-trimethylpentane, commonly known as isooctane, has a rating of 100.

Because straight-run gasoline burns so poorly in engines, petroleum chemists have devised numerous methods for producing higher-quality fuels. One of these methods, catalytic cracking, involves taking the high-boiling kerosene cut (C11–C14) and “cracking” it into smaller branched molecules suitable for use in gasoline. Another process, called reforming, is used to convert C6–C8 alkanes to aromatic compounds such as benzene and toluene, which have substantially higher octane numbers than alkanes. The final product that goes in your tank has an approximate composition of 15% C4–C8 straight-chain alkanes, 25% to 40% C4–C10 branched-chain alkanes, 10% cyclic alkanes, 10% straight-chain and cyclic alkenes, and 25% arenes (aromatics).

Because straight-run gasoline burns so poorly in engines, petroleum chemists have devised numerous methods for producing higher-quality fuels. One of these methods, catalytic cracking, involves taking the high-boiling kerosene cut (C11–C14) and “cracking” it into smaller branched molecules suitable for use in gasoline. Another process, called reforming, is used to convert C6–C8 alkanes to aromatic compounds such as benzene and toluene, which have substantially higher octane numbers than alkanes. The final product that goes in your tank has an approximate composition of 15% C4–C8 straight-chain alkanes, 25% to 40% C4–C10 branched-chain alkanes, 10% cyclic alkanes, 10% straight-chain and cyclic alkenes, and 25% arenes (aromatics).