14.6 Diene Polymers: Natural and Synthetic Rubbers

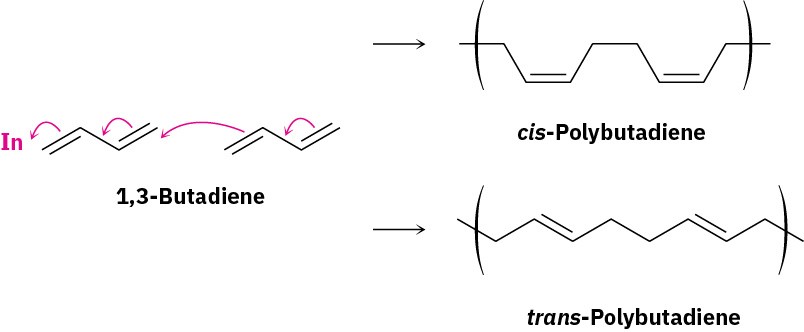

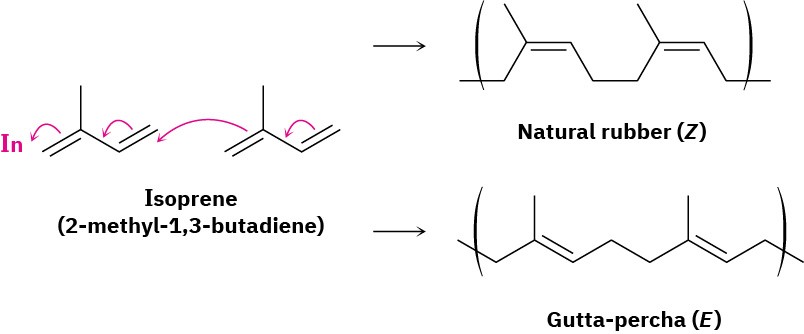

Conjugated dienes can be polymerized just as simple alkenes can (Section 8.10). Diene polymers are structurally more complex than simple alkene polymers, however, because double bonds occur every four carbon atoms along the chain, leading to the possibility of cis–trans isomers. The initiator (In) for the reaction can be either a radical, as occurs in ethylene polymerization, or an acid. Note that the polymerization is a 1,4 addition of the growing chain to a conjugated diene monomer.

Rubber is a naturally occurring diene polymer of isoprene (2-methyl-1,3-butadiene) and is produced by more than 400 different plants. The major source is the so-called rubber tree, Hevea brasiliensis, from which the crude material, called latex, is harvested as it drips from a slice made through the bark. The double bonds of rubber have Z stereochemistry, but gutta-percha, the E isomer of rubber, also occurs naturally. Harder and more brittle than rubber, gutta-percha has a variety of applications, including use in dental endodontics and as the covering on some golf balls.

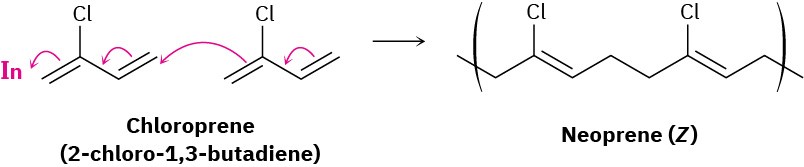

A number of different synthetic rubbers are produced commercially by diene polymerization. Both cis– and trans-polyisoprene can be made, and the synthetic rubber thus produced is similar to the natural material. Chloroprene (2-chloro-1,3-butadiene) is polymerized to yield neoprene, an excellent, although expensive, synthetic rubber with good weather resistance. Neoprene is used in the production of industrial hoses and gloves, among other things.

Both natural and synthetic rubbers are too soft and tacky to be useful until they are hardened by heating with elemental sulfur, a process called vulcanization. Vulcanization cross-links the rubber chains by forming carbon–sulfur bonds between them, thereby hardening and stiffening the polymer. The exact degree of hardening can be varied, yielding material soft enough for automobile tires or hard enough for bowling balls (ebonite).

The unusual ability of rubber to stretch and then contract to its original shape is due to the irregular structure of the polymer chains caused by the double bonds. These double bonds introduce bends and kinks into the polymer chains, thereby preventing neighboring chains from nestling together. When stretched, the randomly coiled chains straighten out and orient along the direction of the pull but are kept from sliding over one another by the cross-links. When the tension is released, the polymer reverts to its original random state.

Problem 14-11

Draw a segment of the polymer that might be prepared from 2-phenyl-1,3-butadiene. Problem 14-12

Show the mechanism of the acid-catalyzed polymerization of 1,3-butadiene.